J

Jacke

Foren-Einsteiger

- Dabei seit

- 18.12.2023

- Beiträge

- 1

Hallo ich habe einen Creality CR10 smart auf klipper umgerüstet mit einem Sonic Pad.

Ich bekomme die erste Schicht nicht hin. Er ist mal zu Hoch und mal zu tief.

Ich Starte die Z probe Calibration und fahre ihn dann soweit runter das er einen Kassenzettel leicht berührt. Dann lasse ich ihn das bedmesh noch abfahren bei Druck Temperatur.

Wenn er druckt ist er in enigen bereichen fast auf dem Bett und es kommt kein filament und in anderen bereichen ist es wie ein Schlange er ist also zu hoch. in der mitte passt es?

am skirt ist es super zu sehn.

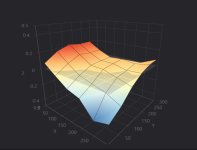

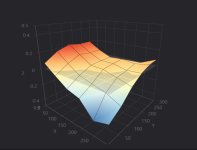

Das ist das Bed

das ist meine printer.cfg

und das mein Start code

Ich habe so langsam keine Idee mehr

Ich bekomme die erste Schicht nicht hin. Er ist mal zu Hoch und mal zu tief.

Ich Starte die Z probe Calibration und fahre ihn dann soweit runter das er einen Kassenzettel leicht berührt. Dann lasse ich ihn das bedmesh noch abfahren bei Druck Temperatur.

Wenn er druckt ist er in enigen bereichen fast auf dem Bett und es kommt kein filament und in anderen bereichen ist es wie ein Schlange er ist also zu hoch. in der mitte passt es?

am skirt ist es super zu sehn.

Das ist das Bed

das ist meine printer.cfg

Code:

# !CR-10 Smart

# printer_size: 300x300x400

# version: 3.6

# This file contains pin mappings for the Creality CR-10 Smart

# with a CRC-2405V1.2 board.

# To use this config, during "make menuconfig" select the STM32F103

# with a "28KiB bootloader" and serial (on USART1 PA10/PA9)

# Flash this firmware on the MCU by copying "out/klipper.bin" to an SD

# card and turning the printer on with the card inserted. The firmware

# filename must end in ".bin" and must not match the last filename

# that was flashed.

# The machine itself includes a small router that can run a Klipper

# frontend. You don't need to buy a single-board computer.

# See docs/Config_Reference.md for a description of parameters.

###fluidd set

[include cx_printer.cfg]

[display_status]

[pause_resume]

[gcode_macro PAUSE]

description: Pause the actual running print

rename_existing: PAUSE_BASE

# change this if you need more or less extrusion

variable_extrude: 1.0

gcode:

##### read E from pause macro #####

{% set E = printer["gcode_macro PAUSE"].extrude|float %}

##### set park positon for x and y #####

# default is your max posion from your printer.cfg

{% set x_park = printer.toolhead.axis_maximum.x|float - 5.0 %}

{% set y_park = printer.toolhead.axis_maximum.y|float - 5.0 %}

##### calculate save lift position #####

{% set max_z = printer.toolhead.axis_maximum.z|float %}

{% set act_z = printer.toolhead.position.z|float %}

{% if act_z < (max_z - 2.0) %}

{% set z_safe = 2.0 %}

{% else %}

{% set z_safe = max_z - act_z %}

{% endif %}

##### end of definitions #####

PAUSE_BASE

G91

{% if printer.extruder.can_extrude|lower == 'true' %}

G1 E-{E} F2100

{% else %}

{action_respond_info("Extruder not hot enough")}

{% endif %}

{% if "xyz" in printer.toolhead.homed_axes %}

G1 Z{z_safe} F900

G90

G1 X{x_park} Y{y_park} F6000

{% else %}

{action_respond_info("Printer not homed")}

{% endif %}

[gcode_macro RESUME]

description: Resume the actual running print

rename_existing: RESUME_BASE

gcode:

##### read E from pause macro #####

{% set E = printer["gcode_macro PAUSE"].extrude|float %}

#### get VELOCITY parameter if specified ####

{% if 'VELOCITY' in params|upper %}

{% set get_params = ('VELOCITY=' + params.VELOCITY) %}

{%else %}

{% set get_params = "" %}

{% endif %}

##### end of definitions #####

{% if printer.extruder.can_extrude|lower == 'true' %}

G91

G1 E{E} F2100

{% else %}

{action_respond_info("Extruder not hot enough")}

{% endif %}

RESUME_BASE {get_params}

[gcode_macro CANCEL_PRINT]

description: Cancel the actual running print

rename_existing: CANCEL_PRINT_BASE

gcode:

TURN_OFF_HEATERS

{% if "xyz" in printer.toolhead.homed_axes %}

G91

G1 Z4.5 F300

G90

{% else %}

{action_respond_info("Printer not homed")}

{% endif %}

G28 X Y

{% set y_park = printer.toolhead.axis_maximum.y|float - 5.0 %}

G1 Y{y_park} F2000

M84

CANCEL_PRINT_BASE

[stepper_x]

step_pin: PB8

dir_pin: !PB7

enable_pin: !PC3

rotation_distance: 40

microsteps: 16

endstop_pin: PC4

position_min: -5

position_endstop: -5

position_max: 305

homing_speed: 80

[stepper_y]

step_pin: PB6

dir_pin: PB5

enable_pin: !PC3

rotation_distance: 40

microsteps: 16

endstop_pin: PC5

position_min: -2

position_endstop: -2

position_max: 302

homing_speed: 80

[stepper_z]

step_pin: PB4

dir_pin: !PB3

enable_pin: !PC3

rotation_distance: 8

microsteps: 16

endstop_pin: probe:z_virtual_endstop

position_min: -3.5

position_max: 405

homing_speed: 4

second_homing_speed: 1

homing_retract_dist: 2.0

[extruder]

max_extrude_only_distance: 1000.0

step_pin: PC2

dir_pin: !PB9

enable_pin: !PC3

rotation_distance: 22.9490304

microsteps: 16

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: PB14

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PB1

control: pid

# tuned for stock hardware with 200 degree Celsius target

pid_Kp: 14.32

pid_Ki: 0.81

pid_Kd: 63.12

min_temp: 0

max_temp: 265

[heater_bed]

heater_pin: PB13

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PB0

control: pid

# tuned for stock hardware with 50 degree Celsius target

pid_Kp: 79.49

pid_Ki: 1.17

pid_Kd: 1349.52

min_temp: 0

max_temp: 120

[idle_timeout]

timeout: 172800

[fan]

pin: PB15

kick_start_time: 1.0

#set heater fan runnig with temperature over 60;

[heater_fan my_nozzle_fan]

pin: PD2

max_power: 1.0

shutdown_speed : 0

heater:extruder

heater_temp : 60

fan_speed : 1.0

[mcu]

serial: /dev/serial/by-id/usb_serial_1

restart_method: command

[probe]

pin: PA4

x_offset: 0.0

y_offset: 0.0

#z_offset: 0

speed: 3

lift_speed: 5

samples_tolerance: 0.05

samples_tolerance_retries: 2

samples: 1

[filament_switch_sensor filament_sensor]

pause_on_runout: true

switch_pin: ^!PA7

[static_digital_output daughterboard_communication]

pins: !PA5

# [bltouch]

# sensor_pin: ^PB1 #signal check port ^stand for pull up

# control_pin: PB0 #singal control prot

# #x_offset: -31.8

# #y_offset: -40.5

# #z_offset: 1.50 #z off_set configuration

# speed: 3.0

# stow_on_each_sample = false #high speed for bltoch,

# samples: 1

# #probe_with_touch_mode = true

[bed_mesh]

probe_count = 6,6

algorithm = lagrange

# probe_count = 5,5

# algorithm = lagrange

# # probe_count = 3,3

# # algorithm = lagrange

speed: 150

mesh_min: 10,10 #need to handle head distance with bl_touch

mesh_max: 295,295 #max probe range

# # # probe_count: 5,5

fade_start: 1

fade_end: 10

fade_target: 0

[safe_z_home]

home_xy_position:150,150

speed: 200

z_hop: 5

z_hop_speed: 3

# [mcu rpi]

# serial: /tmp/klipper_host_mcu

# [adxl345]

# cs_pin: rpi:None

# spi_speed: 2000000

# spi_bus: spidev2.0

# [resonance_tester]

# accel_chip: adxl345

# accel_per_hz: 70

# probe_points:

# 150,150,20

[input_shaper]

shaper_type_x = 2hump_ei

shaper_freq_x = 90.6

shaper_type_y = mzv

shaper_freq_y = 27.2

[gcode_arcs]

#resolution: 1.0

[printer]

kinematics: cartesian

max_velocity: 500

max_accel: 5000

square_corner_velocity: 5.0

max_z_velocity: 10

max_z_accel: 1000

[exclude_object]

[include timelapse.cfg]

[include cx_gmcro.cfg]

#*# <---------------------- SAVE_CONFIG ---------------------->

#*# DO NOT EDIT THIS BLOCK OR BELOW. The contents are auto-generated.

#*#

#*# [bed_mesh default]

#*# version = 1

#*# points =

#*# 0.070000, -0.037500, -0.137500, -0.182500, -0.360000, -0.305000

#*# 0.177500, 0.060000, -0.042500, -0.087500, -0.130000, -0.212500

#*# 0.230000, 0.130000, 0.030000, 0.022500, -0.027500, -0.075000

#*# 0.205000, 0.112500, 0.042500, 0.042500, 0.002500, 0.015000

#*# 0.212500, 0.117500, 0.045000, 0.055000, 0.032500, 0.062500

#*# 0.032500, -0.042500, -0.072500, -0.042500, -0.007500, 0.077500

#*# x_count = 6

#*# y_count = 6

#*# mesh_x_pps = 2

#*# mesh_y_pps = 2

#*# algo = lagrange

#*# tension = 0.2

#*# min_x = 10.0

#*# max_x = 295.0

#*# min_y = 10.0

#*# max_y = 295.0

#*#

#*# [probe]

#*# z_offset = -0.230und das mein Start code

Code:

M220 S100 ;Reset Feedrate

M221 S100 ;Reset Flowrate

G28 ;Home

BED_MESH_PROFILE LOAD=default

G92 E0 ;Reset Extruder

G1 Z2.0 F3000 ;Move Z Axis up

G1 X10.1 Y20 Z0.28 F5000.0 ;Move to start position

M109 S[material_print_temperature_layer_0]

G1 X10.1 Y145.0 Z0.28 F1500.0 E15 ;Draw the first line

G1 X10.4 Y145.0 Z0.28 F5000.0 ;Move to side a little

G1 X10.4 Y20 Z0.28 F1500.0 E30 ;Draw the second line

G92 E0 ;Reset Extruder

G1 E-1.0000 F1800 ;Retract a bit

G1 Z2.0 F3000 ;Move Z Axis up

G1 E0.0000 F1800Ich habe so langsam keine Idee mehr